It’s time for recruitment to be top priority

Latest research from Zellis, a HR and payroll specialist, has revealed that 44% of manufacturing sector employees are planning to leave their roles within the next two years. Brexit, the pandemic, labour shortages and skills gaps have all caused disruption to the UK manufacturing sector, and now organisations are having to tackle another issue that is recruitment and retention.

Building and maintaining a workforce with the right skillset has long been difficult for UK manufacturing businesses. Yet the challenge has intensified, specifically by issues of low unemployment and wage inflation amongst other geopolitical factors.

Make UK reports that 36% of vacancies in manufacturing are proving hard to fill as applicants lack the appropriate skills, qualifications or experience. In comparison, the average rate across all industries is 24%.

The problem cuts across almost the entire workforce. That’s from leadership and management to production and fulfilling orders and continuing operations more generally.

Ageing workforce

Attracting young professionals into manufacturing is a circle the industry is struggling to square. This comes as just 2% of manufacturers’ average workforce age is below the age of 30, as Equinet reveals.

When it comes to drawing new talent into the industry, those born in generation Z often think that working in the manufacturing industry is an old-fashioned, tedious job, with few opportunities to develop within the role.

But manufacturing is in the age of digitalisation. Industry 4.0, the implementation of Internet of Things (IoT) and the increasing use of AI has the potential to help to attract a younger workforce and aid the ageing one too.

By showcasing the industry's modernity and incorporating cutting-edge technologies that improve efficiency and job satisfaction, the reality of the manufacturing industry is far from what it is perceived to be.

Today, there’s a greater understanding that manufacturing is a fundamental part of the UK economy. In fact, a poll carried out by Sheffield Hallam and Savanta has revealed that 93% of the 2,436 people surveyed think that the UK manufacturing industry is important for growing the UK economy, an increase from 70% just five years ago.

Retain and support

As well as getting people into the industry, retaining staff is equally as important. When it comes to staff retention, organisations should start by reviewing their benefits, policies and practices.

Here, ask yourself questions such as, do these encourage older workers to stay longer? Can they work part-time if required? Is there potential for consultancy roles?

Then, see whether such policies encourage or discourage employees from staying longer. It is not uncommon to find that some workers want to be upskilled, to be supported alongside automation or desire a financial reward of some kind.

After all, there’s nothing more valuable than keeping experienced workers on board and allowing them to pass on their knowledge to new recruits.

With that said, when it comes to retention for the older employees, do not approach their long-term future as a succession plan. Instead, help them transfer their skills and allow them to continue to develop their skillset and knowledge, which can be beneficial for all.

And these activities are not exclusively reserved for top leadership. Think about the organisational information top trade professionals have about process, the quirks of the machines or lines they work on and how to work best within and across teams.

Upgrading legacy equipment

According to a survey conducted by software developer Visual Components, prospective talent could be deterred by the fact that 31% of factory machinery is legacy equipment, as the younger generation more accustomed to digital solutions.

The survey goes onto suggest that current employees do not shy away from technological advancements in the factory. In fact, 78% of respondents said there is no hesitancy among their staff to make use of new platforms and, therefore, upskilling being seen as the highest priority.

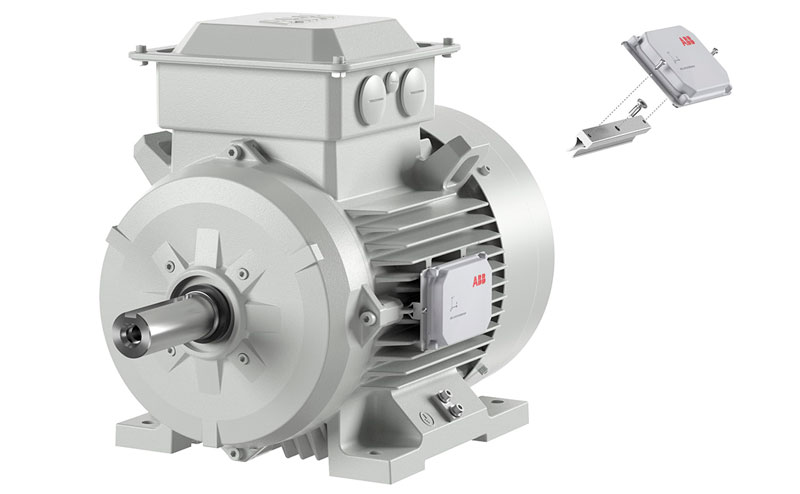

By upgrading legacy systems, employees have the chance to acquire new skills and adapt to modern technologies. For example, to enable the predictive maintenance of motors, manufacturers can purchase the ABB Smart Sensor.

Manufacturers can place these sensors on the motor to convert it into a smart wireless connected device that reports on vibration, temperature and other parameters. Maintenance engineers can use this information to plan maintenance according to machine condition rather than carrying it out at regular and unnecessary intervals, reducing expensive downtime.

In cases like this, turning to a parts supplier helps to upgrade equipment to improved efficiency and streamlined processes, reducing the frustration associated with outdated systems.

Technology, like this, is essential to boosting overall job satisfaction, with employees secure in the knowledge that their company invests in equipment that not only makes their work more efficient and enjoyable, but provides room for upskilling too.

If you would like assistance with digital technologies or would like to source new parts to revive your legacy equipment, then please get in touch.