Overcoming counterfeits once and for all

The market for counterfeit electronics is one of the industry's most widely discussed and analysed topics, yet little headway has been made in solving the problem.

Despite the Paris Convention for the Protection of Industrial Property Act, founded in 1883, along with modern efforts of the International Anti-Counterfeiting Coalition (IACC) formed in 1979, the electronics industry still loses billions of pounds to counterfeit products.

In fact, research from the Anti-Counterfeiting Forum estimates that the proliferation of counterfeit goods has resulted in a cost of £30bn, or the equivalent of 14,800 jobs, for the UK economy. Therefore, it’s no surprise that the increasing volume of counterfeit electronics entering the UK is of particular concern to UK-based original equipment manufacturers (OEMs).

To avoid significant financial losses and potential risks associated with counterfeit goods, here are the most crucial steps to take when identifying and mitigating the infiltration of fake automation parts across the supply chain.

Vetting parts

If a product is believed to be counterfeit, it is crucial to check that the product or reference numbers on the label or packaging correspond with the expected part.

This involves scrutinising the components and their labels to detect discrepancies or inconsistencies.

For obsolete parts, we opt for a hands-on approach to our counterfeit control. This comes as dealing with obsolete parts presents a unique set of challenges due to a lack of original documentation or manufacturers no longer providing support or information about these components.

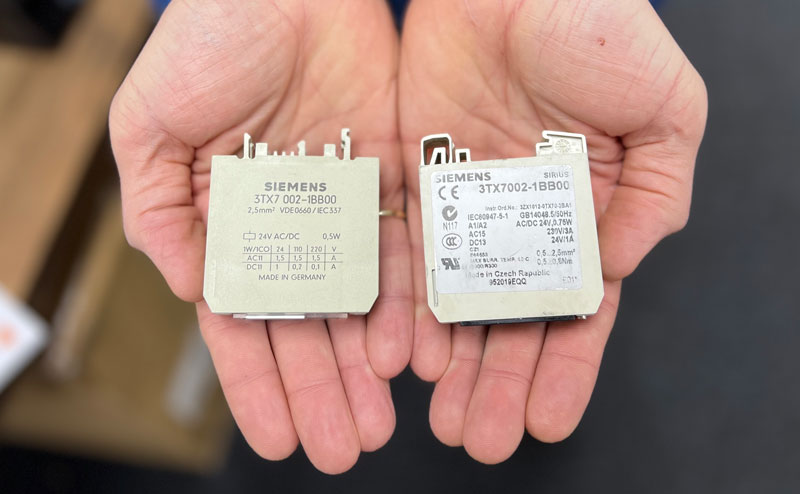

In these instances, Foxmere will scrutinise the product and its labels against the same or similar products from the same manufacturer.

Regarding the current active stock, label scanning technology is the best way to read and verify the authenticity of labels on automation parts effectively and in real time.

New suppliers

In current times, diversifying your supplier base to increase resilience in the supply chain has never been so important. However, when dealing with new suppliers, it is just as important to vet them with the same level of detail as when vetting parts.

When working with new suppliers, placing a sample order is a good rule of thumb. Additionally, for more obscure parts, it sometimes helps to buy duplicate items from a known, reputable supplier for comparison.

Value experience

Staff members of automaton parts suppliers, such as Foxmere, manually vet automation parts — thoroughly examining the physical characteristics of the item and its accompanying boxes and labels.

This manual inspection is critical in identifying any differences or signs of counterfeiting that may not be apparent through automated processes, especially as some pose added complexity, like the aforementioned challenges of working with obsolete parts.

Just look at the part numbers — every manufacturer uses its own special format. For example, Siemens uses special alphanumeric codes that signify family and revision numbers, while companies, such as Phoenix Contact, simply opt for a numerical ID.

Moreover, not all products have part numbers and some products may have multiple serial numbers that correspond to different components or parts.

Having scanned, assessed and reviewed millions of parts, the Foxmere team is well-placed to spot any counterfeit that tries to infiltrate the supply chain. Reliability is a key factor as to why we have such strong relationships with our customers, including global brands such as Danone, Johnson and Johnson and BIC.

If we are to make headway in solving the counterfeit problem, a reliable supply chain must include credible partners that vet their obscure, old and obsolete parts.

If you would like to source reliable parts with the assurance that they are counterfeit-free, then please get in touch via our contact page.