The 6 types of manufacturing processes

Although the drives and controls we use for modern manufacturing are constantly evolving, most businesses still use one of the six main manufacturing processes. Continue reading to learn more about the different types of manufacturing processes and how they're used in the wild.

Repetitive manufacturing

As the name may imply, repetitive manufacturing is characterised by the repetitive assembly of standardised products or components continuously or semi-continuously.

In this manufacturing approach, the same or similar items are produced in large quantities over an extended period with minimal variation in the production process. It is commonly used in industries where there is a high demand for uniform products and where economies of scale can be achieved through mass production.

Discrete manufacturing

Discrete manufacturing involves the production of products that might form part of a larger product or unit. Unlike repetitive manufacturing processes, where goods are produced continuously, discrete manufacturing entails assembling or fabricating separate items with unique identities.

Imagine a process that takes individual parts, components, and sub-assemblies and brings them together to create a finished product, like a car — that’s discrete manufacturing, and it is a popular approach with smartphone manufacturers, automotive, and the aerospace industry.

Job shop manufacturing

Job shop manufacturing embraces limited automation, focusing instead on smaller, customised product batches. In contrast to mass production applications, job shops are equipped to handle a diverse range of products, often with varying designs, materials and production requirements.

This manufacturing process usually involves production areas or workstations rather than production lines, making it a popular choice with artisan jewellery, clothing and furniture manufacturers.

Continuous process manufacturing

Sometimes known as continuous manufacturing, process manufacturing is similar to repetitive manufacturing. However, the main difference between process manufacturing and repetitive manufacturing is that process manufacturing generally involves using raw materials that undergo some kind of transformation or chemical reaction.

This method is commonly used in the chemical industry, pharmaceutical manufacturing and food processing, where large volumes of homogeneous products are required.

Batch process manufacturing

Like job shop and discrete manufacturing, batch processing allows manufacturers to cater to more extensive consumer requirements, treating each job as a unique 'batch'. When all the goods from one batch have completed a particular stage, they move on to the next stage together. Every finished product from one batch should be identical.

Batch process manufacturing offers advantages such as reduced setup times, easier quality control, and the ability to produce multiple products with shared equipment, making it well-suited for industries with diverse product portfolios or changing customer preferences.

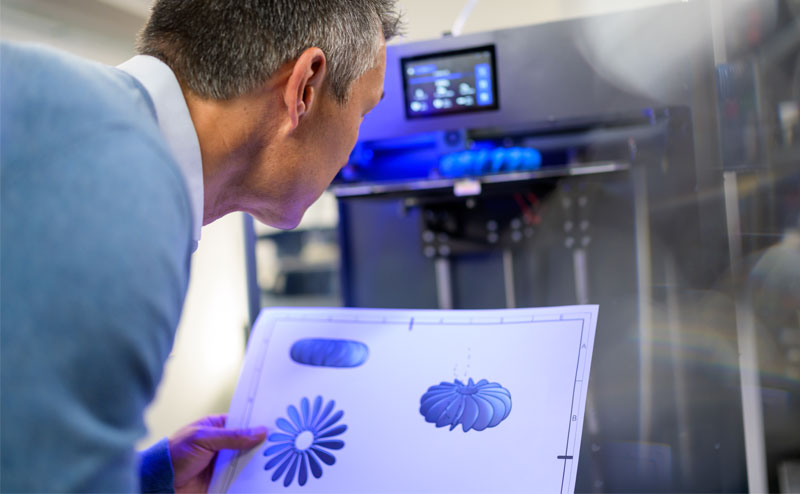

3D printing

Sometimes called additive manufacturing, 3D printing is one of this list's most modern manufacturing processes. With very low overheads, manufacturers can print complete products with composites and materials, such as plastics and metals.

This versatile manufacturing method is superb for prototyping and tooling, allowing manufacturers to see projects from design to prototype rapidly and at a relatively low cost.

To conclude, it’s probably fair to agree that regardless of which manufacturing process you use, keeping it online is essential, and that’s where a reliable automation partner like Foxmere comes in.

At Foxmere, we supply thousands of manufacturers of all sizes — from startups to Fortune 500s — with automation parts daily. Our speciality is helping manufacturers with PLCs, drives, HMIs, motors, safety equipment, etc. Contact us today for more information or to simply ask for a quotation.